How Cement is Made

Did you know…

After water, concrete (mainly cement) is the most widely used commodity on the planet.

Cement is a crucial ingredient in concrete.

It binds everything together and allows companies to construct the buildings we live and work in and the roads we drive on each and every day. Amrize products are in 80% of buildings and roads in Western Canada.

What are the materials used to make cement?

75 to 85% Limestone (CaCO 3 )

2 to 5% Silica (Si)

1.5 to 3.5% Alumina (Al) and

0.5 to 1% Iron (Fe)

1.5 to 6% Gypsum

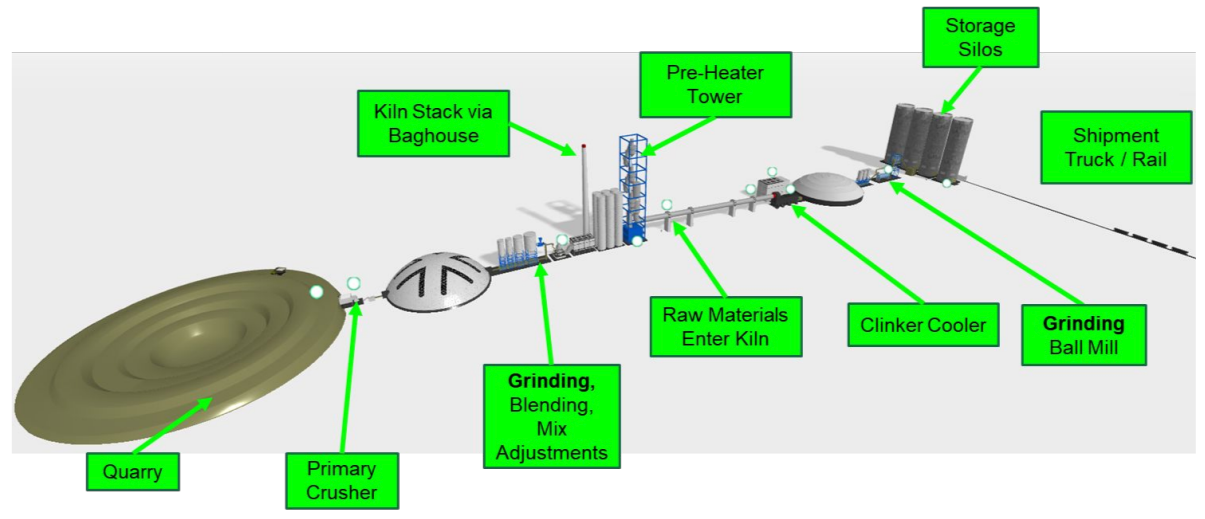

The manufacturing process

There are six stages in the manufacturing process:

1. Crushing and grinding the raw materials that are pulled out of the Exshaw quarries

2. The materials are then blended into the correct proportions

3. The prepared mix is heated (pyroprocessing) in a kiln

4. The pyroprocessed product is then grinded into what’s called “clinker”

5. Adding gypsum controls how long the cement will take to set, and other materials are added, depending on the type of product

6. The cement gets shipped by rail or truck to a distribution centre for bagging

The difference between Concrete and Cement